Definition

Dimmers are devices used to vary the brightness of a light. By decreasing or increasing the RMS voltage and hence the mean power to the lamp it is possible to vary the intensity of the light output.

Basics

Although variable-voltage devices are used for various

purposes, the term dimmer is generally reserved for those intended to

control lighting.

Dimmers range in size from small units the size of a normal

lightswitch used for domestic lighting to high power units used in

large theatre

or architectural lighting installations. Small domestic dimmers are

generally directly controlled, although remote control systems (such as

X10) are available. Modern professional dimmers are generally controlled by a digital control system like DMX.

In the professional lighting industry changes in intensity are

called “fades” and can be “fades up” or “fades down”. Dimmers with

direct manual control had a limit on the speed they could be varied at

but this issue is pretty much gone with modern digital units (although

very fast changes in brightness may still be avoided for other reasons

like lamp life).

They are used instead of variable resistors because they have higher efficiency.

A variable resistor would dissipate power by heat (efficiency as low as

0.5). By switching on and off, theoretically a dimmer does not heat up

(efficiency close to 1.0).

History

One of the earliest recorded dimmers is Granville Woods's "Safety Dimmer", published in 1890; dimmers before that were liable to cause fires.

Early dimmers were directly controlled through the manual

manipulation of large dimmer panels, but this meant that all power had

to come through the lighting control location, which could be

inconvenient and potentially dangerous, especially with systems that

had a large number of channels, high power lights or both (such as a stage disco or other similar venues).

When thyristor dimmers came into use, analog remote control systems (often 0-10V lighting control

systems) became feasible. The wire for the control systems was much

smaller (with low current and lower danger) than the heavy power cables

of previous lighting systems. Each dimmer had its own control wires

which meant a huge number of wires leaving the lighting control

location and running to each individual dimmer. Modern systems use a

digital control protocol such as DMX to control a large number of dimmers (and other stage equipment) through a single cable.

In 1961 Joel Spira, founder of Lutron Electronics, invented the

first solid state dimmer, which switches the current on and off 120

times per second, saving energy and allowing the dimmer to be installed

in a standard electrical wallbox.

Types of dimmer

Early examples of a dimmer include a salt water dimmer. In a salt

water dimmer, there were two metal contacts in a glass beaker. One

contact was on the bottom, while the other was able to move up and

down. The closer the contacts to each other, the higher the level of

the light. Using salt water dimmers was a tedious and precarious task

that included filling the beakers with water, checking the

concentration of the salt, and raising or lowering the top contact.

Salt water dimmers were not efficient due to the evaporation of water

and the corrosion of the many metal pieces. These dimmers were

colloquially known as "pis pots", for obvious reasons. Many old theatre

electricians still recount stories of how they were initiated into the

art by being requested to "top up a pot" and receiving a shock, as

unbeknownst to them the pot was live...

Dimmers were also often based on rheostats.

These were inefficient; when set to the middle brightness levels, they

could dissipate as heat a significant portion of the power rating of

the load (up to 25% for resistive loads, more for temperature dependent

loads like lamps) so they were physically large and required plenty of

cooling air. Also, because their dimming effect depended a great deal

on the total load applied to each rheostat, the load needed to be

matched fairly carefully to the power rating of the rheostat. Finally,

as they relied on mechanical control they were slow and it was

difficult to change many channels at a time.

Variable autotransformers

(often referred to as variacs) were then introduced. While they were

still nearly as large as rheostat dimmers, they were highly efficient

devices and their dimming effect was independent of the load applied so

it was far easier to design the lighting that would be attached to each

autotransformer channel. Remote control of the dimmers was still

impractical, although some dimmers (typically, for "house light" use)

were equipped with motor drives that could slowly and steadily reduce

or increase the brightness of the attached lamps. Whilst variacs have

fallen out of use for lighting they are still used in other

applications such as under/overvoltage testing of equipment due to the

fact they deliver a reasonably pure sine wave output and produce no

radio frequency noise.

Thyristor (and briefly, thyratron)

dimmers were introduced to solve some of these problems. Because they

use switching techniques instead of potential division there is almost

no wasted power, dimming can be almost instantanious and is easily

controlled by remote electronics. Triacs are used instead of SCR

thyristors in lower cost designs, but do not have the surge handling

capacity of back-to-back SCR's, and are only suitable for loads less

than about 20 Amps. The switches generate some heat during switching,

and can cause interference. Large inductors

are used as part of the circuitry to suppress this interference. When

the dimmer is at 50% power the switches are switching their highest

voltage (>300 V in Europe) and the sudden surge of power causes the

coils on the inductor to move, creating buzzing sound associated with

some types of dimmer; this same effect can be heard in the filaments of the incandescent lamps

as "singing". The suppression circuitry adds a lot of weight to the

dimmer, and is often insufficient to prevent buzzing to be heard on

audio systems that share the mains supply with the lighting loads. This

development also made it possible to make dimmers small enough to be

used in place of normal domestic light switches. European dimmers must

comply with relevant EMC legislation requirements; this involves suppressing the emissions described above to limits described in EN55104.

An alternative to the leading-edge dimming that is typically used

with SCRs is trailing edge dimming, where the falling part of the

waveform is cut rather than the rising part. This is most often used in

devices that use a switched-mode power supplies that need the front of the waveform complete so that it may cut itself.

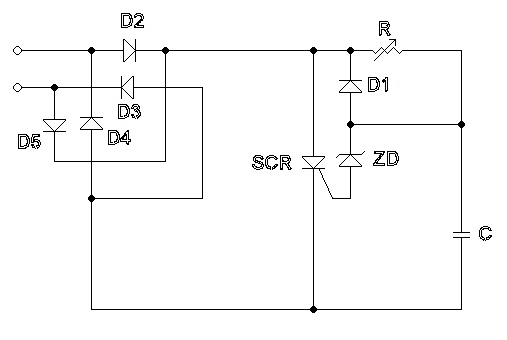

A typical SCR based light dimmer which dims

the light through phase angle control. This unit is wired in series

with the load. Diodes (D2, D3, D4 and D5)

form a bridge which generates DC with lots of ripple. R and C form a

circuit with a time constant, as the voltage increases from zero (at

the start of every halfwave) C will charge up, when C is able to make

ZD conduct and inject current into the SCR the SCR will fire. When the

SCR conducts then D1 will discharge C via the SCR. The SCR

will shut off when the current falls to zero when the supply voltage

drops at the end of the half cycle, ready for the circuit to start work

on the next half cycle.

Sine-wave dimming promises to solve the weight and interference issues that afflict thyristor dimmers. These are effectively high power switched-mode power supplies. They rely on a new generation of insulated gate bipolar transistors (IGBTs) which are still relatively expensive.

Control

See Lighting control console

Non domestic dimmers are usually controlled remotely by means of

various protocols. Analogue dimmers usually require a separate wire for

each channel of dimming carrying a voltage between 0 and 10 V.

Some analogue circuitry then derives a control signal from this and the

mains supply for the switches. As more channels are added to the system

more wires are needed between the lighting controller and the dimmers.

In the late 70s serial analogue protocols were developed. These

multiplexed a series of analogue levels onto a single wire, with

embedded clocking signal similar to a composite video signal (in the

case of Strand Lighting's European D54 standard, handling 384 dimmers) or separate clocking signal (in the case of the US standard AMX192).

Digital protocols, such as DMX512 have proved to be the answer since the late 80s. In early implementations a digital signal was sent from the controller to a demultiplexer,

which sat next to the dimmers. This converted the digital signal into a

collection of 0 to +10 V or 0 to -10 V signals which could be connected

to the individual analogue control circuits.

Modern dimmer designs use microprocessors to convert the digital

signal directly into a control signal for the switches. This has many

advantages, giving closer control over the dimming, and giving the

opportunity for diagnostic feedback to be sent digitally back to the

lighting controller.

Patching

Dimmers are usually arranged together in racks, where they can be

accessed easily, and then cables are run to the instruments being

controlled. In architectural installations cables are run straight from

the dimmers to the lights. However venues such as theatres demand more

flexibility. The lighting rig may change dramatically for each show,

and occasionally during shows. Many theatres have cables run

permanently to sockets (called circuits) around the theatre, however

not all the sockets are needed for each show, so there will be fewer

dimmers than there are circuits. A patch bay usually sits next to the

dimmers enabling the dimmers to be connected to specific circuits. The

patch bay may also enable many circuits to be connected to one dimmer

and even series connection for low-voltage lamps. This patch bay is

known as the mains or hard patch. Analogue dimmers may also have a soft

patch to match output channels from the lighting controller to control

selected dimmers. Most new installations do not use patch bays, instead

they use a dimmer-per-circuit and patch dimmers into channels using a

computerized control consoles.

Dimming curves

The design of most analogue dimmers meant that the output of the

dimmer was not directly proportional to the input. Instead, as the

operator brought up a fader the dimmer would dim slowly at first, then

quickly in the middle, then slowly at the top. The shape of the curve

resembled that of the third quarter of a sine wave. Different dimmers

produced different dimmer curves, and different applications typically

demanded different responses.

Television often uses a "Square" law, providing finer control in top

part of the curve, essential to allow accurate trimming of the colour

temperature of TV lighting. Theatrical dimmers tend to use a softer "S

curve" or linear curve. Digital dimmers can be made to have whatever

curve the manufacturer desires and may have a choice between a linear

relationship and selection of different curves, so that they can be

matched with older analogue dimmers. Sophisticated systems provide

user-programmable or non-standard curves, and a common use of a

non-standard curve it to turn a dimmer into a "non-dim", switching on

at a user defined control level.

Example dimmer curves:

Preheat

Some types of incandescent (filament) lamps should not be switched to full power from cold, and doing so can shorten their life dramatically owing to the large inrush current that occurs. To soften the blow to the lamps slightly, dimmers may have a preheat

function. This sets a minimum level, usually around 5-10%, which is not

obvious to the audience, but stops the lamp from cooling down too much.

This also speeds up the instrument's reaction to sudden bursts of power

which operators of rock'n'roll style shows appreciate. The opposite of

this function is sometimes called top-set. This limits the maximum power supplied to an instrument, which can also extend its life.

The digital revolution

Modern digital desks can emulate preheat and dimmer curves and allow

a soft patch to be done in memory. This is often preferred as it means

that the dimmer rack can be exchanged for another one without having to

transfer complicated settings.

Rise time

One measure of the quality of the dimmer is the "rise time". The

rise time in this context is the amount of time it takes within the cut

part of the waveform to get from the zero-point crossover to the start

of the uncut part of the waveform. A longer rise time reduces the noise

of the dimmer and the lamp as well as extending the life of the lamp.

Unsurprisingly, a longer rise time is more expensive to implement than

a short one, this is because the size of choke has to be increased.

Source: Wikipedia (All text is available under the terms of the GNU Free Documentation License and Creative Commons Attribution-ShareAlike License.)

|